- Details

- Parameters

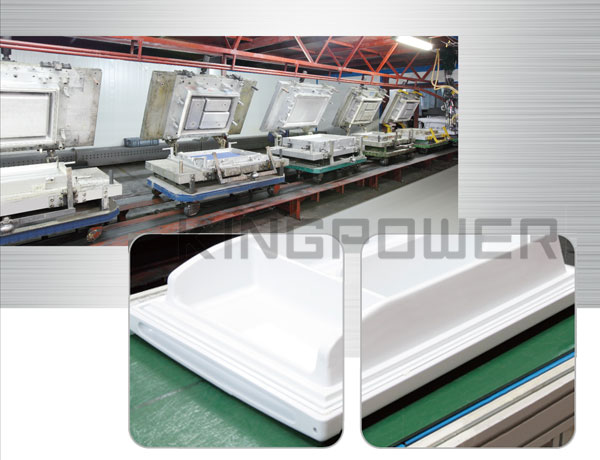

The foaming line consists of a chain drive system, foaming fixtures, ovens, foaming machine platform, steam heating and exhaust system, filling robot arm, unlocking mechanism, conveying trolley, opening and closing cover guide rail, auxiliary locking device, as well as supporting pneumatic system, hydraulic system, electronic control system and other parts. The foaming line mainly consists of manual (automatic) upper box (door), fixture mold closing, manual (automatic) vertical filling, cycle driving, heating and curing cycle, fixture unlocking, fixture opening, manual (automatic) lower box (door), cleaning and other processes.

This foaming line has the characteristics of compact structure, simple operation, smooth transmission, convenient product replacement, and high production efficiency.

General technical performance parameters

Dimensions:~29500 × 7950 × 3350mm (LXWXH)

Number of positions: 26

Fixture template size: 2000 × 900mm;

Mold frame closing height: 200 mm (can be determined according to customer requirements)

Production cycle time: 20s (excluding manual operation time)

Heating method: steam heating or oil mold temperature machine heating

Foam medium: POL mixed with cyclopentane+ISO or POL mixed with 141b+ISO

Injection method: manual vertical filling with mold opening

Steam capacity: 200M ³/h

Curing oven temperature: 55 ± 5 ℃

Steam temperature: 120-150 ℃

Compressed air source: working pressure ≥ 0.5Mpa, flow rate approximately 0.1m ³/min

Capacity: Heating with steam, approximately 25Kw (3890V, 50Hz)

Heating with oil mold temperature machine: approximately 145Kw