- Details

- Parameters

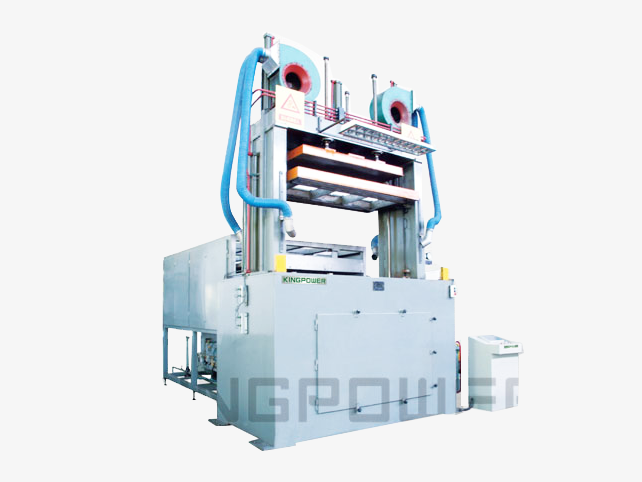

The single station vacuum forming machine consists of heating and forming parts, and is mainly used for vacuum adsorption forming of refrigerator door linings and box liners. The equipment adopts PLC control and touch screen operation, which can control each heating temperature zone point by point, and adopts hydraulic proportional control technology to make the equipment run more smoothly.

Process: manual feeding, automatic pressing, heating, foaming, forming, cooling, and manual material retrieval.

This device has the characteristics of simple structure, easy operation, and suitability for forming large products.

The single station vacuum forming machine consists of heating and forming parts, and is mainly used for vacuum adsorption forming of refrigerator door linings and box liners. The equipment adopts PLC control and touch screen operation, which can control each heating temperature zone point by point, and adopts hydraulic proportional control technology to make the equipment run more smoothly.

Process: manual feeding, automatic pressing, heating, foaming, forming, cooling, and manual material retrieval.

This device has the characteristics of simple structure, easy operation, and suitability for forming large products.

General technical performance parameters:

Forming area: 1800mm * 800mm

Molding depth: 650mm

Heating power:~126Kw

Total electrical capacity:~176Kw (380V, 50Hz)

Forming method: convex and concave mold forming

Beat: Container liner ≤ 170 seconds/mold, door lining ≤ 60 seconds/mold (excluding manual loading and unloading time)

Compressed air source: 2 "(0.5Mpa~0.65Mpa)

Water source: 6T/H (industrial water)

Product materials: ABS, HIPS, PS

Product material thickness: 1.0mm~6.0mm

Note: If customers have special process requirements, they can customize according to their needs.