- Details

- Parameters

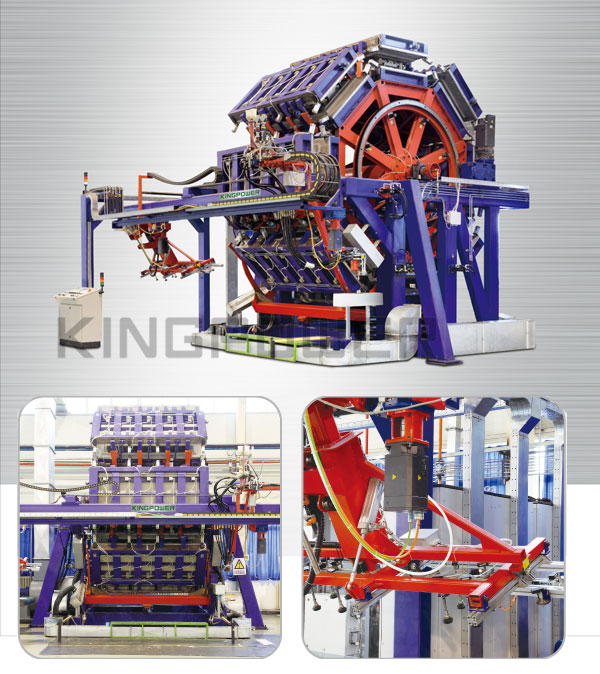

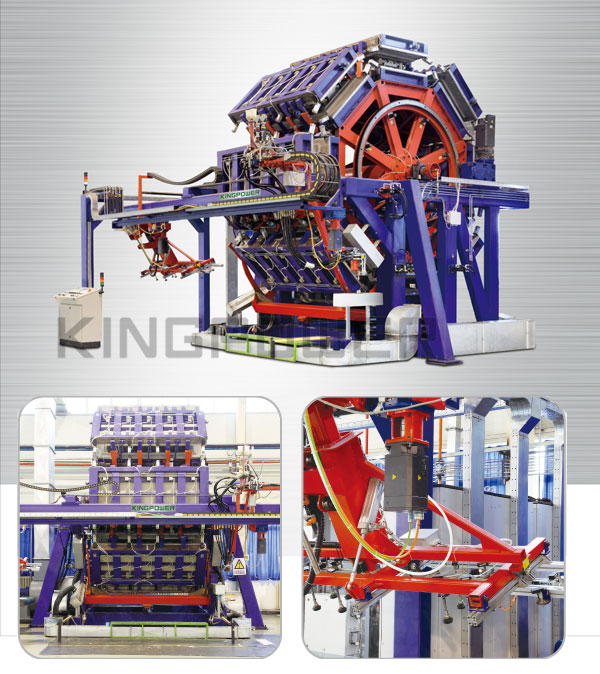

This foaming line is a rotary (hub type) seven (eight) station door foaming equipment, mainly used for foaming the doors of refrigerators (cabinets). It consists of the main frame, rotating frame, foam mold frame, hydraulic drive, positioning, opening and closing mold system, injection and transfer system, variety identification system, as well as supporting hydraulic system, electronic control system and other parts.

The foaming line consists of manual picking and placing of workpieces, automatic return filling, rotating mold closing, oil cylinder mold locking, completion of curing, oil cylinder unlocking, lowering of the lower mold frame to the original position for mold opening, and operator's ability to remove the finished door body

Each template of the fixture is heated with water. Mold clamping is safe and reliable, mold replacement is convenient and fast, and suitable for flexible production of multiple varieties. The production line has the characteristics of small footprint, compact structure, and easy operation.

This foaming line is a rotary (hub type) seven (eight) station door foaming equipment, mainly used for foaming the doors of refrigerators (cabinets). It consists of the main frame, rotating frame, foam mold frame, hydraulic drive, positioning, opening and closing mold system, injection and transfer system, variety identification system, as well as supporting hydraulic system, electronic control system and other parts.

The foaming line consists of manual picking and placing of workpieces, automatic return filling, rotating mold closing, oil cylinder mold locking, completion of curing, oil cylinder unlocking, lowering of the lower mold frame to the original position for mold opening, and operator's ability to remove the finished door body

Each template of the fixture is heated with water. Mold clamping is safe and reliable, mold replacement is convenient and fast, and suitable for flexible production of multiple varieties. The production line has the characteristics of small footprint, compact structure, and easy operation.

通用技术性能参数

外形尺寸(长×宽×高)约:6000×5500×4600mm

工位数:7 (8)

夹具模板尺寸(长×宽): 2000mm×900mm

模架闭合高度:200mm

生产节拍: 46s (不含人工操作时间)

发泡介质: POL混环戊烷+ISO或POL混141b+ISO

注料方式: 开模自动充注

加热方式: 模温机水加热

电容量:~65KW(3890V、50Hz)