- Details

- Parameters

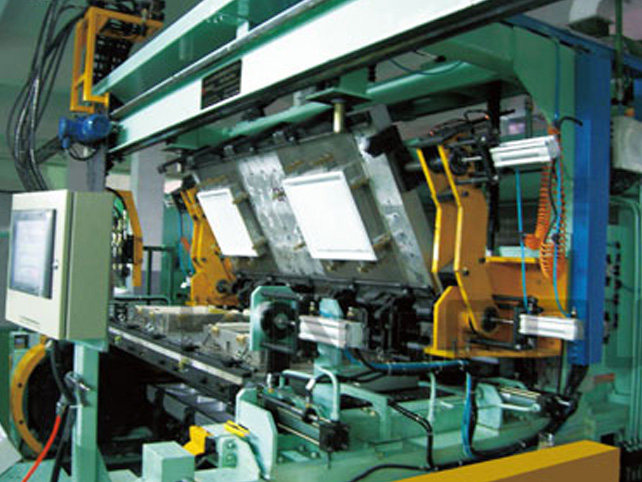

This foaming line is a track type door foaming line, mainly suitable for foaming production of refrigerator or freezer doors. It consists of a main frame, a track type transmission device, a mold frame component, a mold frame installation vehicle, a mold frame lifting device, a rotating mold opening device, an automatic filling manipulator, a heating system, an opening and closing lock device, a safety exhaust system, a curing oven, an equipotential grounding system, and supporting pneumatic system, hydraulic system, electronic control system, etc.

The foaming line consists of pre installed door manual feeding, automatic filling, mold closing, mold frame lowering and locking, cyclic curing, unlocking, mold frame lifting and opening, manual unloading and other processes.

The production line has 10 workstations with equal lifting and circular transmission. The mold frame has a horizontal lifting function before mold opening to avoid squeezing the door body when the mold frame rotates for mold opening. This line has the characteristics of safety and reliability, compact structure, small footprint, high efficiency, and suitability for flexible production of multiple varieties.

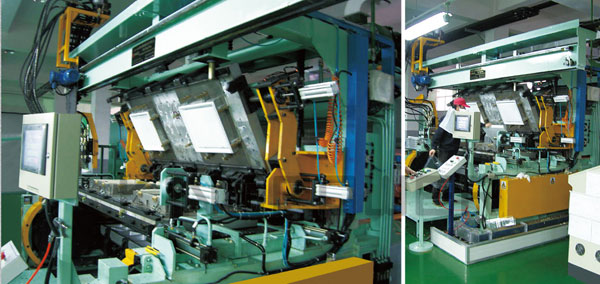

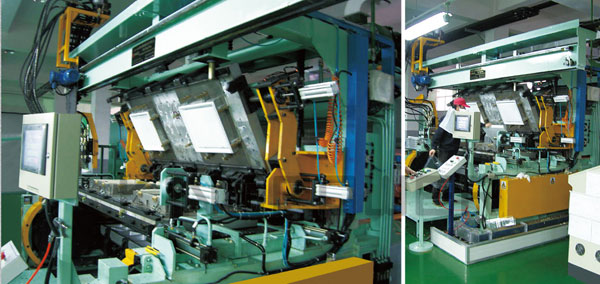

This foaming line is a track type door foaming line, mainly suitable for foaming production of refrigerator or freezer doors. It consists of a main frame, a track type transmission device, a mold frame component, a mold frame installation vehicle, a mold frame lifting device, a rotating mold opening device, an automatic filling manipulator, a heating system, an opening and closing lock device, a safety exhaust system, a curing oven, an equipotential grounding system, and supporting pneumatic system, hydraulic system, electronic control system, etc.

The foaming line consists of pre installed door manual feeding, automatic filling, mold closing, mold frame lowering and locking, cyclic curing, unlocking, mold frame lifting and opening, manual unloading and other processes.

The production line has 10 workstations with equal lifting and circular transmission. The mold frame has a horizontal lifting function before mold opening to avoid squeezing the door body when the mold frame rotates for mold opening. This line has the characteristics of safety and reliability, compact structure, small footprint, high efficiency, and suitability for flexible production of multiple varieties.

General technical performance parameters:

Dimensions:~95000 * 5000 * 4000 copies (L * W * H)

Number of positions: 10-12

Fixture template size: 2000mm * 900mm (L * W)

Mold frame closure height: 200mm

Production cycle time: 50s (excluding manual operation time)

Heating method: steam heating or oil mold temperature machine heating;

Foam medium: POL mixed with cyclopentane+ISO mixed with 141b+ISO

Injection method: automatic filling by mold opening

Curing oven temperature: adjustable from 35 to 70 ° C

Compressed air source: working pressure ≥ 0.5Mpa, flow rate approximately 0.1m ³/min

Capacity: Heating with steam, approximately 35Kw (3890V, 50Hz)

Heating with oil mold temperature machine: approximately 135Kw

Note: If customers have special process requirements, they can customize according to their needs.