- Details

- Parameters

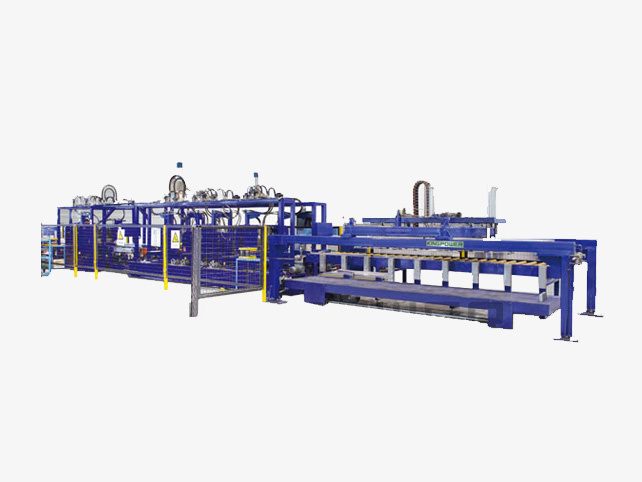

The refrigerator U-shell forming line is a fully automated production line. The forming line is mainly composed of an automatic feeding machine, a punching and cutting machine, a 180 ° flipping machine, a rolling mill, a Z-stacking and edging machine, a step hole punching and flipping and end bending machine, a laminating line, a U-shaped bending machine, a mechanical lower material, and supporting pneumatic system, hydraulic system, electronic control system, etc.

According to product requirements, each specialized machine can be freely combined to complete processes such as automatic feeding, punching and trimming, sheet flipping, roll forming, Z-shaped edge wrapping, step hole punching and end folding, condenser covering, U-shaped bending, and cutting of fixed length sheet metal.

This production line has the advantages of reasonable process layout, high production efficiency, good automation level, safe and reliable human-machine interface operation, convenient maintenance, and adaptability to a wide range of products.

General technical performance parameters:

Production line dimensions (reference): 45000 * 3500 * 2000mm (L * X * H)

Equipment working height: 900mm

Number of positions: 9

Folding depth: 400~650mm

Folding height: 450~2000mm

Folding U width: 450-700mm

Production cycle: 25s/pcs

Sheet material: cold-rolled sheet, pre coated sheet, laminated PCM sheet

Sheet thickness: 0.45~0.6mm

Capacity: 40Kw

Gas consumption:~2m ³/h

Note: If customers have special process requirements, they can customize according to their needs.